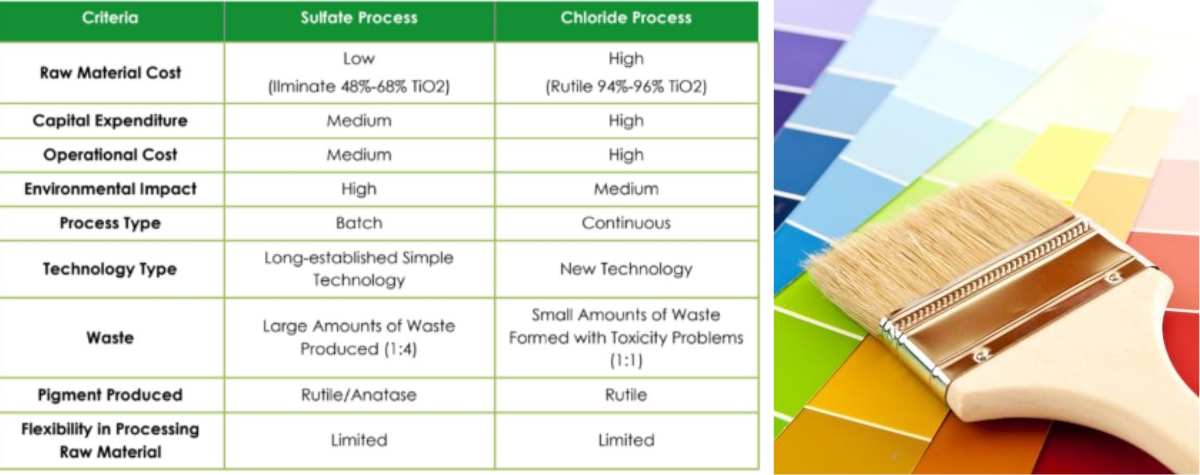

Titanium dioxide, a best white pigments due to the unique properties such as: scattering power, hiding power, stabilizing and being chemically inert. In the industrial scale, TiO2 have been manufactured in two different methods: the older sulfate (since the 1920s) and the newer one, chloride (since the late 1950s).

Today, there is close to 5 million tones of titanium dioxide pigments capacity in the world, whereas around 55% represents chloride and 45% sulfate process. So here the key question comes: Is the chloride products better than sulfate or the opposite?

Well, the answer is not easy since both types of pigments have their advantages and disadvantages, depending on the application area in which they are used. Historically, the chloride material was considered as a better one owing to its cleaner technology, which meant fewer impurities in the final product, resulting in brighter color and bluer undertone than in the case of sulfate. However, the sulfate titanium dioxide producers have done a lot of technological investments over the last five decades. Today, there are many high quality products of sulfate origin, which can be as good as their chloride counter-types, bringing such significant properties as: great dispersibility, good color and appearance, opacity and high durability or often most important – economical effect to the end-use sector. This is a very remarkable fact about some sulfate based product, in the times where many economies are suffering weaker demand and downward price pressure to the industries.

(Source : Titan Crimia & some of the data are taken from ECS conference 2012)