HPMC and MHEC have similar functions in building materials.

It can be used as dispersant, water retaining agent, thickener and binder, etc. it is mainly used in the molding of cement mortar and gypsum products. It is used in cement mortar to increase its cohesiveness, workability, reduce flocculation, improve viscosity and shrinkage, and has the functions of water retention, reducing water loss on concrete surface, improving strength, preventing cracks and water-soluble salt weathering. It is widely used in cement, plaster, mortar and other materials.

It can be used as film-forming agent, thickener, emulsifier and stabilizer in latex coatings and water-soluble resin coatings. It has good wear resistance, uniformity and adhesion, and improves surface tension, acid-base stability and compatibility with metal pigments. Due to its good viscosity storage stability, it is especially suitable for emulsion coatings as dispersant. In a word, although the amount of the system is small, it has a great effect and is widely used.

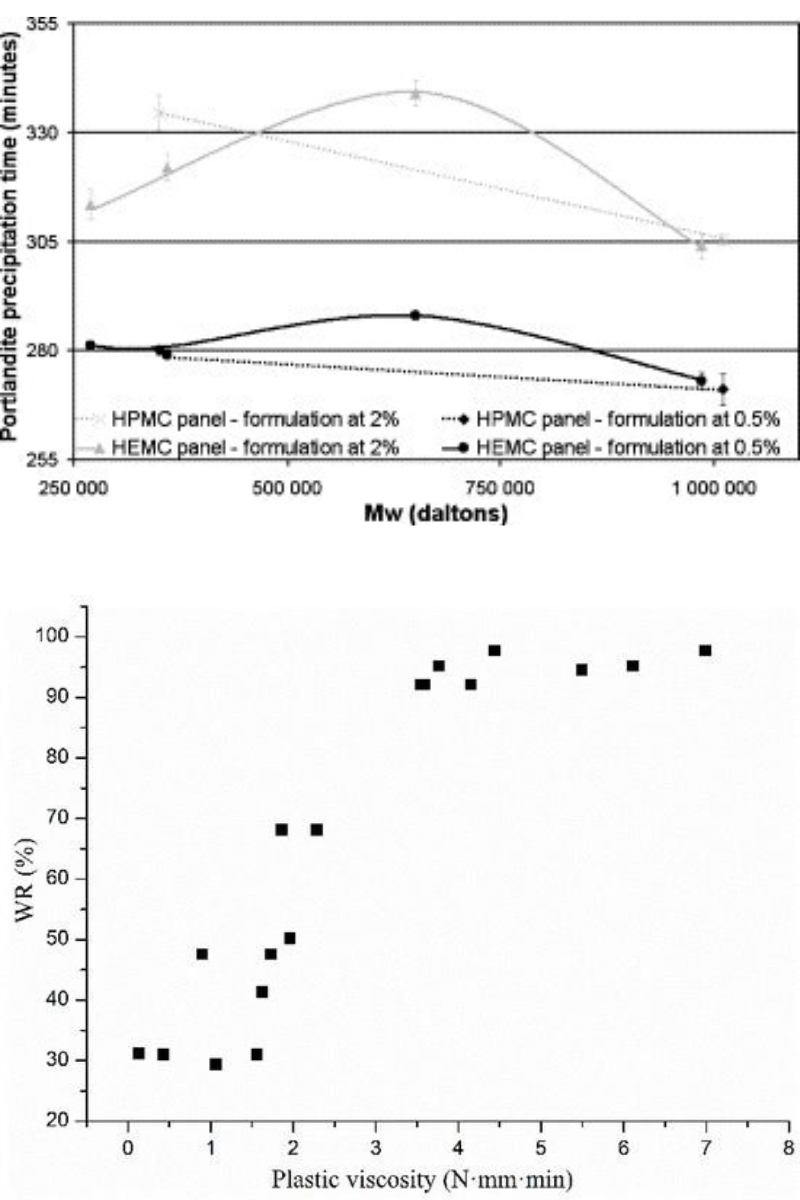

The gel temperature of cellulose ether determines its thermal stability in application.

The gel temperature of HPMC is usually at 60℃-75℃ depending on the type, group content and different production processes of different manufacturers. Due to the characteristics of MHEC group, it has a higher gel temperature, usually above 80℃, so its stability under high temperature is better than HPMC. In practical application, in the hot construction environment in summer, the water holding capacity of MHEC with the same viscosity and dosage is better than that of HPMC. Cellulose ether with low gel temperature will lose its thickening and water retention at high temperature, thus accelerating the hardening of cement and mortar, and directly affects the construction and cracking resistance.

Because there are more hydrophilic groups in the structure ofMHEC, it has better hydrophilicity. The water retention rate of MHEC in mortar is slightly higher than that of HPMC at the same dosage of products with the same viscosity. In addition, the vertical flow resistance of MHEC is also relatively good. Therefore, the application of MHEC in ceramic tile adhesive and wall putty is better performances.